Swan Seals specializes in providing high-quality sealing solutions for the Food & Beverage industry. We offer a comprehensive range of FDA-approved seals and gaskets designed to meet the stringent hygiene and safety standards required in food and beverage processing environments.

Applications We Serve

Our sealing products are suitable for a variety of applications within the Food & Beverage sector, including:

- Breweries

- Bakeries

- Dairy Processing

- Beverage Production

- Meat Processing

- Oil & Fat Manufacturing

- Pet Food Production

- Ready Meal Preparation

Typical machinery and systems we support include:

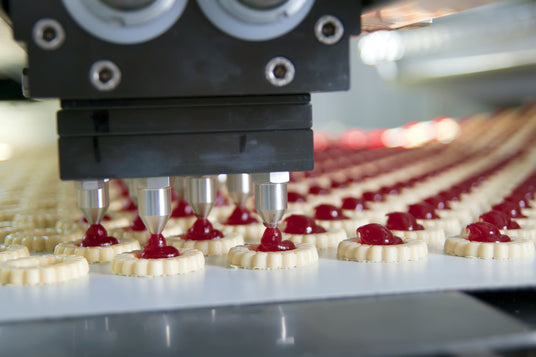

- Food Depositors

- Bottling, Canning & Capping Equipment

- Filling & Portioning Systems

- Production Lines

- Decorating & Injection Systems Plant Machinery (e.g., compressors, bagging machines, refrigeration units)

- Grinding & Forming Equipment (e.g., mincers, patty formers

Products & Services

- Custom-Made Seals

- O-Rings with Certificates of Conformity & Batch Traceability

- Depositor Seals

- Ring Type Joint Seals

- Spreader & Disperser Seals

- Heat Exchanger Seals

- Rotary Seals

- Gaskets (Spiral Wound, Graphite, Standard Sheet)

- Tri Clamp Seals & Gaskets for pipe couplings

- SMS & IDF Joint Rings

- PTFE Spring Energised Seals

- DIN & D Seals

- Encapsulated O-Rings & Gaskets (including Camlock Gaskets)

- Hygienic Seals for ISO1127, ISO2852 & ISO2853 Fittings

- Metal Detectable Products

Our products are manufactured from FDA-approved materials such as Blue Acetal, Red & Blue Polyurethane, EPDM, FPM/FKM (Viton), NBR, Silicone, PTFE, FFKM (Karez), PEEK, PCTFE, and UHMWPE.

Expert Technical Support

At Swan Seals, we offer expert technical advice to help you overcome your sealing challenges. Our team collaborates closely with clients to design and manufacture custom seals that meet specific application requirements. With in-house manufacturing capabilities, we provide flexible solutions with quick turnaround times, no minimum order quantities, and no expensive moulding charges.